- Home

- Sheets

- Flat and curved sheets

- Lamiera TTRain

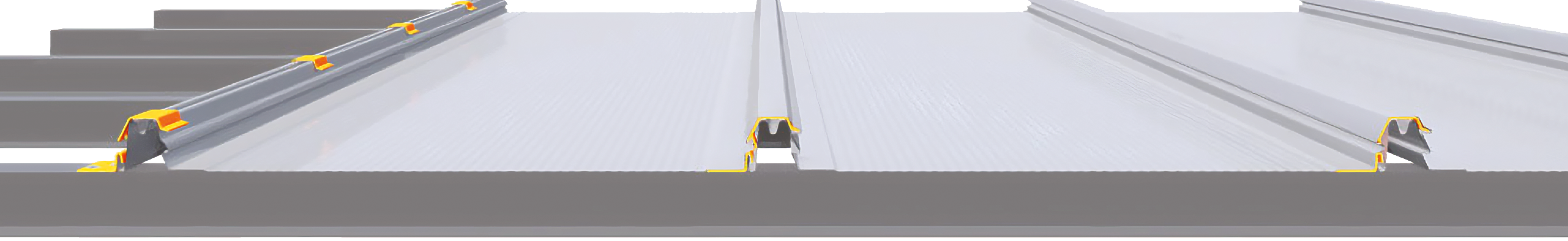

Lamiera TTRain

Seamless sheet metal with a joint that eliminates the need for drilling in aesthetic coverings

TT Rain is the innovative metal roofing system with drainage joints. Worked in a single piece with the same length as the plane of the roof, it offers guaranteed waterproofing even with low gradients and without the use of sealants or gaskets, thanks to the dual overlappingdraining channel and the lack of fastening holes.

The lengthwise pleated ribbing creates a rigid metal sheet and makes it easier for rainwater to run off even with low gradients. Flexible and sturdy, 5754 H18/28 aluminium alloy guarantees a superior performance compared to traditional alloys used. The front re-flanging creates a fold preventing infiltrations of rising water into the gutter and into the ridge. Produced directly on site or at heights for long roof planes, it is a definitive solution that is maintenance-free yet offers an incomparable performance.

Thanks to the multiple coupling system, the TTRain can be anchored enabling the roofing sheets to slide freely as a result of thermal expansion. Made in coated stainless steel, and plastic covering eliminates any risk of galvanic corrosion between the different metals. The bracket is placed between the ribbing of the metal sheet, so the roofing rests on the supporting structure, making the roof system extremely strong so it can be walked on with confidence.

The TT Rain Clip is an aluminium clip for securing light roofing accessories like the finishing flashing and photovoltaic stringers. Simple click fastening without the need to drill holes, leaving the roof covering free to shift to accommodate thermal expansion. The dual support plate represents the space where the accessory element is secured without drilling the roofing.

For long roof planes and sheets that cannot be transported, Lattonedil has the solution with its mobile manufacturing unit. The profiling machine in a container with its own tractor is ideal for the most challenging sites.

The machinery is light and so the production unit can be lifted off the ground, eliminating the tricky and hazardous handling of long sheets made at ground level. This helps save time and increases site safety. The machinery has its own genset so the production of the sheets has its own independent power supply.

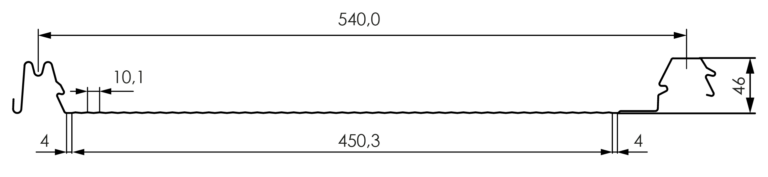

SPECIFICATIONS:

- Useful sheet width: 540 mm;

- Edge height: 46 mm;

- 5754 aluminium alloy;

- Sheets in a single piece equal to the length of the roof plane without overlapping;

- Roof secured without holes, using brackets that safeguard unrestricted thermal expansion;

- Dual overlapping drainage channel;

- Guaranteed water seal without gradient;

- Outstanding load capacity and walkability;

- Exceptional resistance to positive and pressures thanks to the multiple coupling steel bracket;

- Roof resting on the supporting beams and roof insulation;

- Front re-flanging creates a fold in the gutter or ridge;

- Lengthwise pleated ribbing

Certificate